Product Description

HRC Wholesale High Flexible Spider Jaw Coupling Pump Marine Shaft Coupling Price

Basic information:

| Material | Genuine material |

| Feature | 1) One-stop Shopping Experience 2) Different Quality Levels for Customers to Choose 3) Full Excavator Parts Product Lines |

| Classification | HRC Wholesale High Flexible Spider Jaw Coupling Pump Marine Shaft Coupling Price |

| OEM service | Yes |

| Payment | T/T, Western Union, etc. |

| Port | HangZhou |

| Quotation | Based on OEM parts or genuine parts, packing, quantity and other requirements |

| MOQ | For many products, we don’t have MOQ limited. |

| Application | HRC Wholesale High Flexible Spider Jaw Coupling Pump Marine Shaft Coupling Price |

About us:

specialized in:

couplings, rubber mounts, gear parts, hydraulic seals, and seal kits for hydraulic hammers, rock breakers, hydraulic excavators, wheel loaders, and JCB backhoe loaders.

And, Our company also supplies:

Engine parts, hydraulic piston pump and hydraulic travel motor, Swing motor assembly and hydraulic component parts, electric parts, etc. Hydraulic hammer breaker parts with piston, cylinder, chisel, through bolt, side bolt, top bush, front head bushing,accumulator, valve, etc.

We always try our best for all our customers and make it better and better. Welcome!

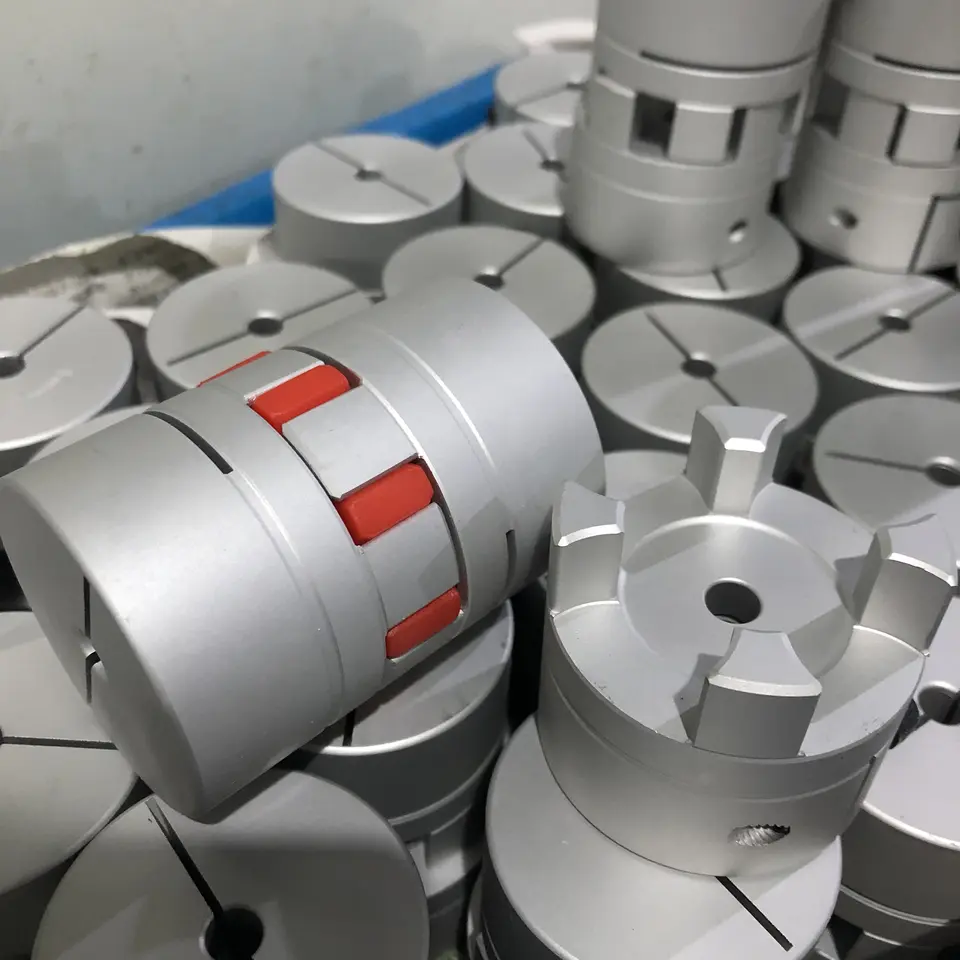

Products Show:

FAQ:

– What is your core activity (do you deal with engine replacement parts, fuel system, undercarriage, etc)?

We mainly do the couplings, seal kits, hydraulic parts, solenoids, electric parts, gear parts, bearings, and other excavator spare parts.

– Which kind of machinery do you work with (bulldozers, front loaders, graders, excavators, etc)?

We mainly do the spare parts for excavators. But sometimes to meet customers’ requirements, we will do the sourcing for the customers for their needs for loader parts, air compressor parts, and so on.

– Do you have the stock?

Most of our products are in stock.

– Can you send us the price lists (so that we do not always bother you when we need the price info)?

Sorry that we don’t have a price list. You’re welcome to contact us if you need anything.

Accommodating Variable Operating Conditions and Loads with Jaw Couplings

Jaw couplings are designed to accommodate variable operating conditions and loads, making them suitable for a wide range of applications. Here’s how jaw couplings achieve this:

- Flexibility: The elastomeric spider (flexible element) in a jaw coupling provides flexibility, allowing for angular, parallel, and axial misalignment between the connected shafts. This flexibility helps to compensate for minor misalignments that may occur during operation or due to changes in operating conditions.

- Shock Absorption: The elastomeric spider also acts as a shock absorber, dampening vibrations and reducing the impact of sudden loads or shocks. This feature is particularly beneficial in applications where the connected equipment may experience variable or unpredictable loads.

- Torsional Stiffness Options: Jaw couplings are available in different torsional stiffness options, depending on the specific application requirements. Couplings with higher torsional stiffness are suitable for precision applications with minimal misalignment, while those with lower stiffness are ideal for applications with higher misalignment and shock absorption needs.

- Material Selection: Jaw couplings can be manufactured from various materials, such as aluminum, steel, or stainless steel, to suit different environmental conditions and loads. Corrosion-resistant materials are available for harsh environments, ensuring the coupling’s performance remains unaffected by changing operating conditions.

- Size and Torque Ratings: Jaw couplings are available in a wide range of sizes and torque ratings, allowing users to select the appropriate coupling based on the expected operating conditions and torque requirements of the application. It’s essential to choose a coupling size that comfortably handles the maximum expected load.

- Interchangeability: Many jaw couplings are designed to be interchangeable with other manufacturers’ couplings of the same size and type. This feature provides flexibility in sourcing replacements and makes it easier to adapt the coupling to changing requirements or equipment configurations.

Overall, jaw couplings’ ability to handle variable operating conditions, misalignments, and loads makes them versatile and reliable components in a wide range of mechanical systems and applications.

Can jaw couplings be used in heavy-duty applications such as mining and construction?

Yes, jaw couplings can be used in heavy-duty applications such as mining and construction, but their suitability depends on various factors. Jaw couplings are commonly employed in a wide range of industrial applications due to their versatility and ability to handle misalignment. However, when considering their usage in heavy-duty environments, several important aspects need to be taken into account:

- Torque and Power Requirements: Heavy-duty applications often involve high torque and power demands. It is crucial to ensure that the selected jaw coupling is rated to handle the specific torque and power levels encountered in the mining and construction machinery. Choosing a coupling with a sufficient torque capacity ensures reliable power transmission without premature failure.

- Material Strength: The materials used in the construction of jaw couplings play a critical role in their ability to withstand heavy-duty applications. Couplings made from robust materials, such as high-strength steel or alloy materials, are better suited for withstanding the demanding conditions found in mining and construction equipment.

- Impact and Shock Resistance: Mining and construction applications involve significant levels of impact and shock loads due to the nature of the work. The jaw coupling must be designed to handle these dynamic loads without compromising its structural integrity. Some jaw couplings feature specially designed elastomers or flexible elements that provide additional shock absorption and reduce the transmitted impact forces.

- Dust and Debris Management: Heavy-duty environments like mining and construction sites often contain high levels of dust, dirt, and debris. These particles can accumulate on the coupling surfaces and lead to premature wear and reduced performance. Selecting jaw couplings with appropriate sealing mechanisms or protective covers can help minimize the ingress of contaminants and extend the coupling’s life in such environments.

- Maintenance and Inspection: Regular maintenance and inspection are crucial in heavy-duty applications to identify any signs of wear, misalignment, or damage to the coupling. Proper maintenance practices can prevent unexpected failures and ensure the equipment operates efficiently and safely.

When considering the use of jaw couplings in heavy-duty applications like mining and construction, it is essential to consult with coupling manufacturers or engineering experts to select the appropriate coupling type and size for the specific application. Some heavy-duty applications might require more specialized coupling designs, such as grid couplings, gear couplings, or disc couplings, which are explicitly engineered for extreme conditions and higher torque capacities. Additionally, following the manufacturer’s guidelines and recommendations for coupling installation, maintenance, and operating parameters is critical to ensure reliable and safe operation in heavy-duty environments.

Can Jaw Couplings Accommodate High Torque and High-Speed Applications?

Jaw couplings are versatile and can handle a wide range of torque and speed requirements. However, their suitability for high torque and high-speed applications depends on the specific design and material of the coupling.

Advancements in jaw coupling technology and the use of high-strength materials, such as steel and aluminum, have significantly improved their performance capabilities. For many industrial applications, jaw couplings can efficiently accommodate high torque and high-speed requirements.

When selecting a jaw coupling for high torque and high-speed applications, consider the following factors:

- Coupling Size: Choose a jaw coupling size that matches the torque and speed requirements of the application. Larger couplings with bigger spider elements can handle higher torque loads.

- Material: Opt for jaw couplings made from robust materials like steel or aluminum, which can withstand higher torque and speed without compromising structural integrity.

- Design: Some jaw coupling designs are better suited for high torque applications, offering increased torque capacity and better performance under heavy loads.

- Service Factor: Consider the service factor, which accounts for peak or intermittent loads, to ensure the selected jaw coupling can handle temporary torque spikes.

It’s essential to consult with coupling manufacturers or industry experts to determine the most suitable jaw coupling for specific high torque and high-speed applications. Properly sized and selected jaw couplings can provide reliable and efficient power transmission in demanding industrial scenarios.

editor by CX 2023-11-27